Individual manufacturing Services from DROSTAMA

DROSTAMA guarantees precise production of your parts. We value precision and speed. As a small, high-performance machining company, we can react to your orders with speed and flexibility – in contrast to large companies. Our speciality is the production of prototypes and small series with subsequent professional processing and finishing.

DROSTAMA guarantees precise production of your parts. We value precision and speed. As a small, high-performance machining company, we can react to your orders with speed and flexibility – in contrast to large companies. Our speciality is the production of prototypes and small series with subsequent professional processing and finishing.

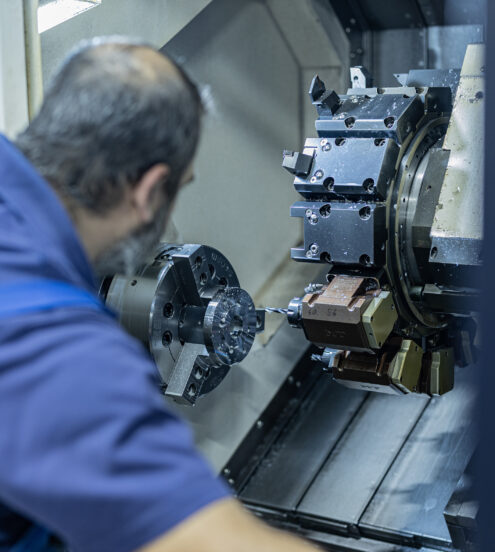

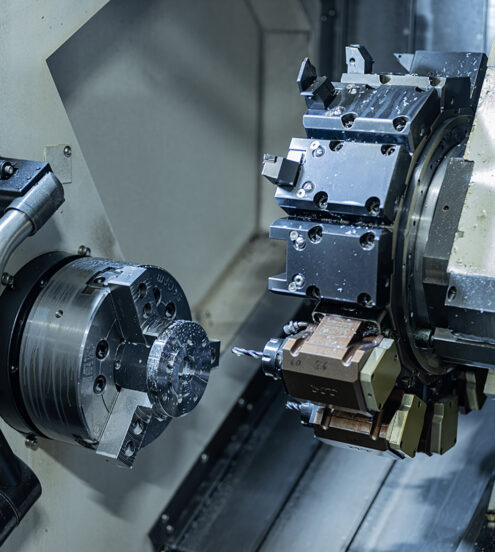

Our high-performance machinery is operated by our trained employees, who continuously monitor dimensional accuracy and material quality in order to supply you with the best workpieces.

Materials we process

- Stainless steel

- Aluminium

- Structural steels

- Stainless steels

- Hastelloy

- AW7075

- C45N

- 42CRM04QT

- 1.4301

- 1.4305

- 1.4571

- S355

- CUAL10Fe3Mn2

Machining technology

our services

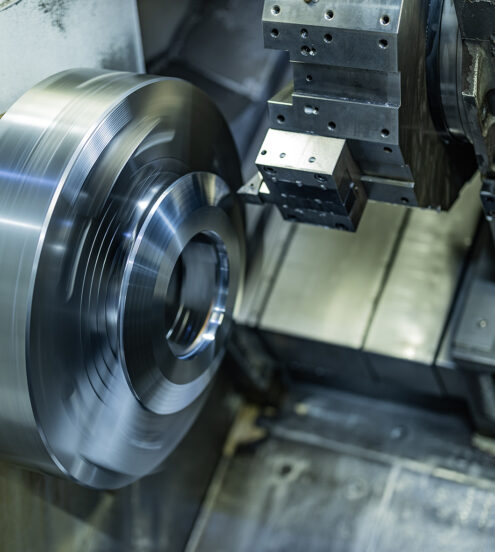

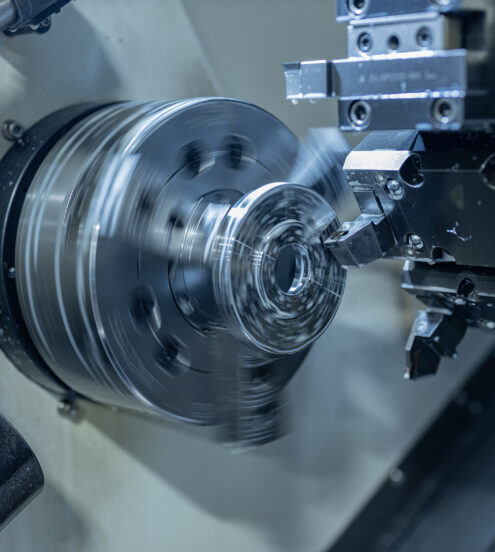

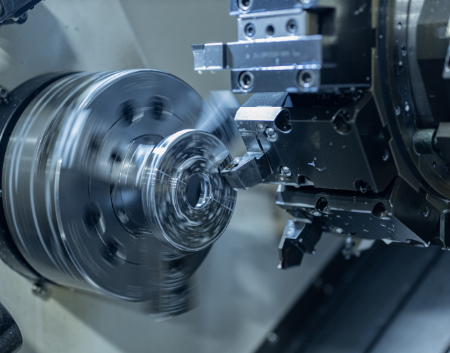

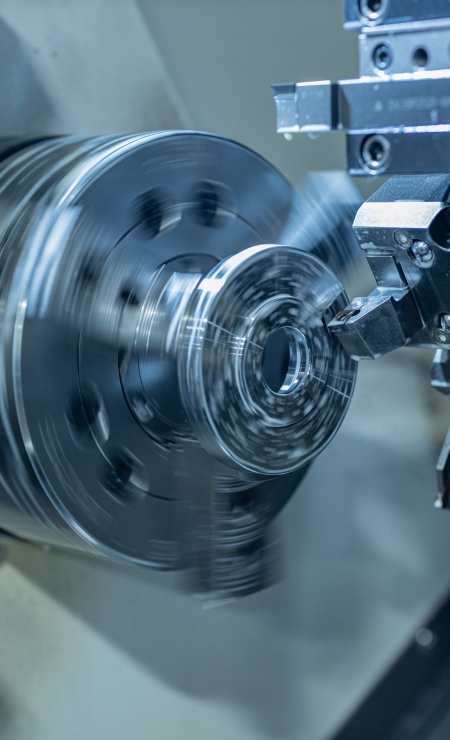

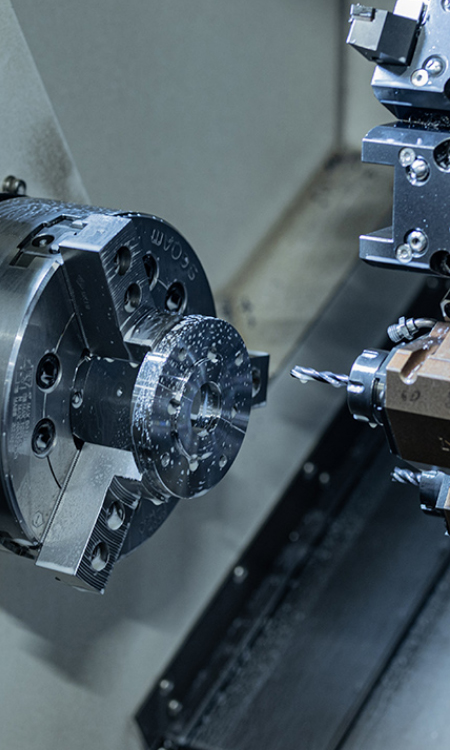

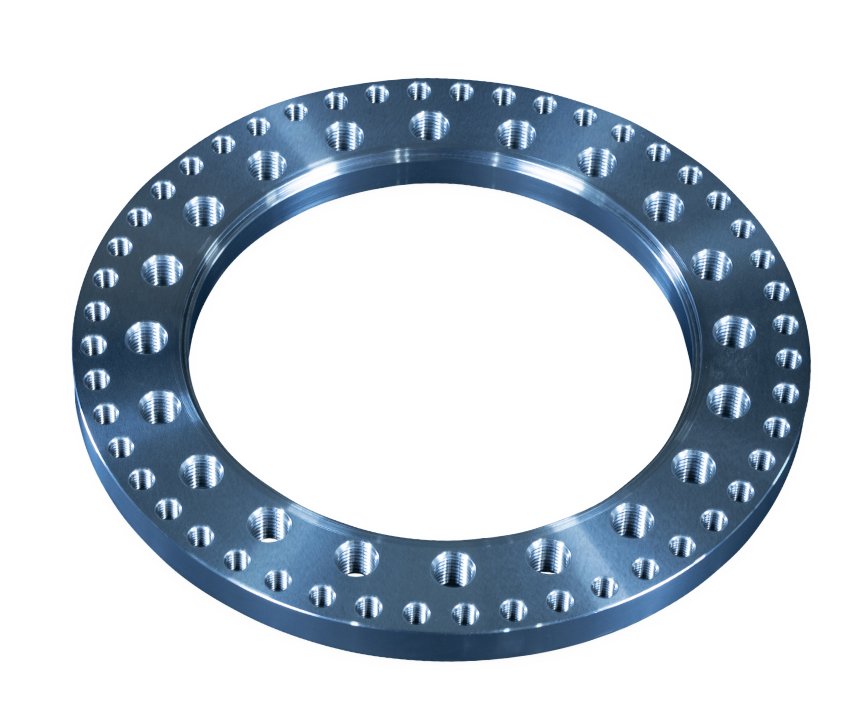

Lathing

We lathe your workpieces up to a diameter of 1000 mm and a turning length of 2000 mm. We manufacture all common materials, prototypes, individual and series parts precisely and rapidly.

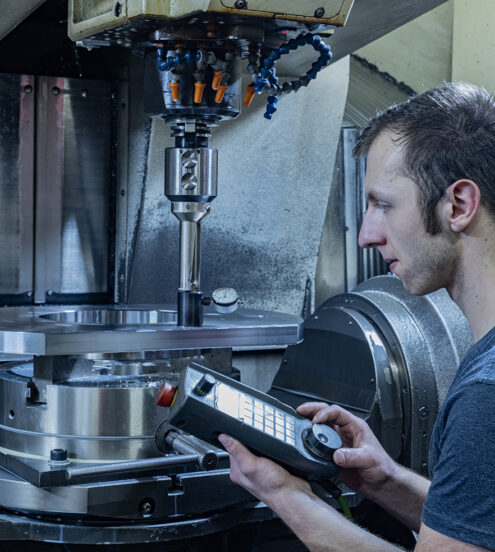

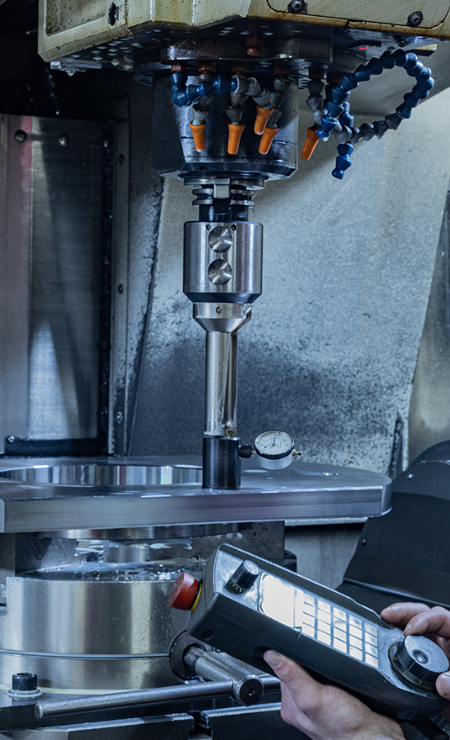

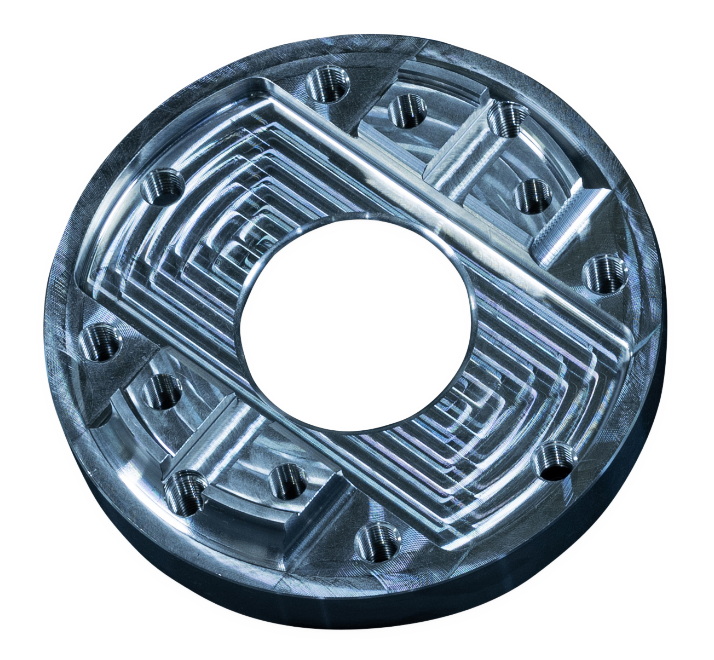

Milling

Our versatile machinery enables us to mill parts up to 1800x1000x1000 mm. Our CNC machining centres have three or five machining axes and guarantee high-quality implementation of your orders.

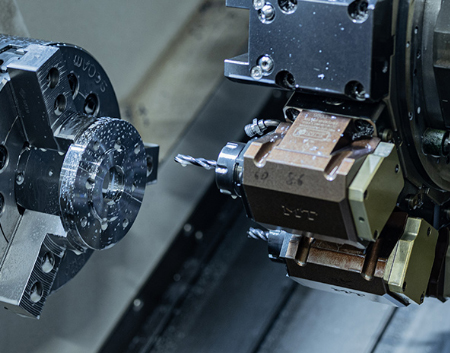

Drilling

Our modern CNC lathes with driven tools work with the utmost precision. This allows us to scale your parts individually and machine them in fewer set-ups.

Galerie

Lathing

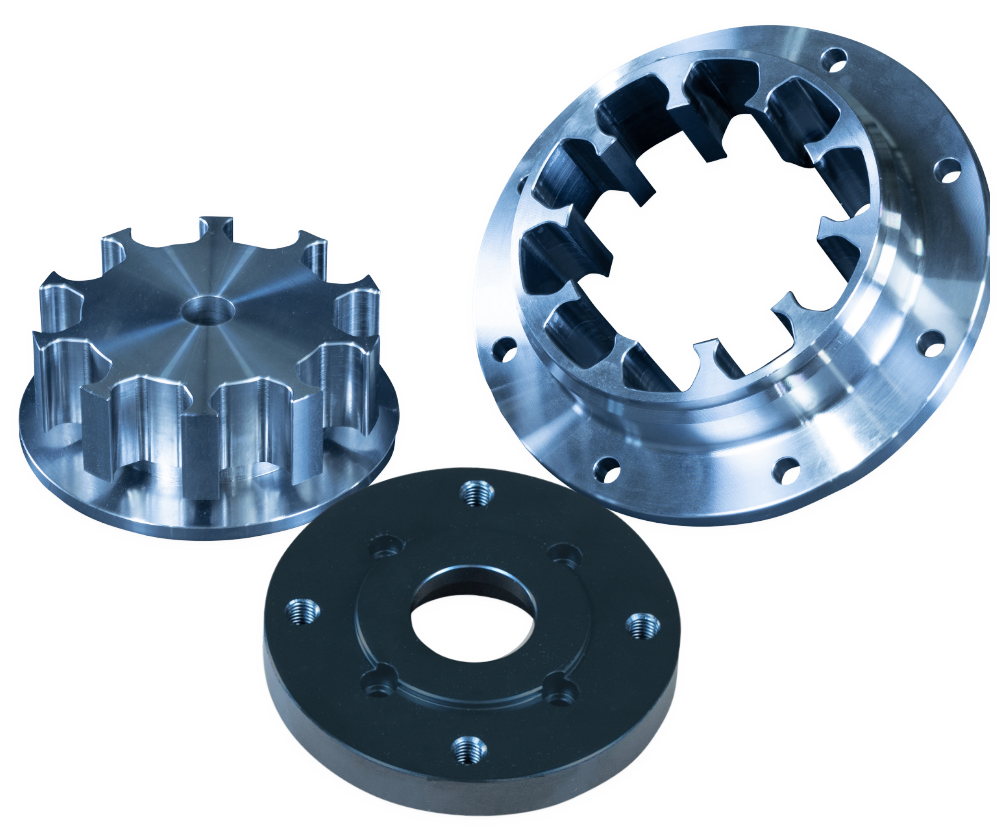

With a high degree of dimensional accuracy, we also transform complex lathed parts into the desired shape. In our modern, professional production we primarily manufacture parts up to a diameter of 1000 mm and a turning length of 2000 mm. Our services include the production of high-quality components for couplings in construction machinery and ships as well as other safety-relevant parts for crane systems and wind turbines.

We guarantee you a consistently high standard of quality. Even safety-relevant parts with standardised material and processing specifications are no challenge for us.

Advantages

- Up to a diameter of 1000 mm and a turning length of 2000 mm

- Precise manufacturing

- Flexible processing of your orders

- Shaft manufacturing

- Machining of all common materials

Gallery

Milling

We manufacture your orders quickly, reliably and economically with our modern machinery. Our highly efficient machining centres are equipped with 3 to 5 axes and ensure precise production of prototypes, individual parts, small series and series. In our quality assurance we regularly check the dimensional accuracy of your components as well as the material quality.

Advantages

- Precise manufacturing

- Parts up to 1800x1000x1000 mm

- Verified dimensional accuracy and material quality

- Individual marking with a marking device

- 3D measurement of the parts

Gallery

Drilling

Thanks to our modern CNC lathes with driven tools, we can manufacture your components really economically.

We can machine all common materials and special alloys.

Advantages

- Economical machining

- Lathing, drilling and thread cutting possible in one set-up

Gallery

What else we offer you

- Welding

- Grooving

- Pulling

- Striking

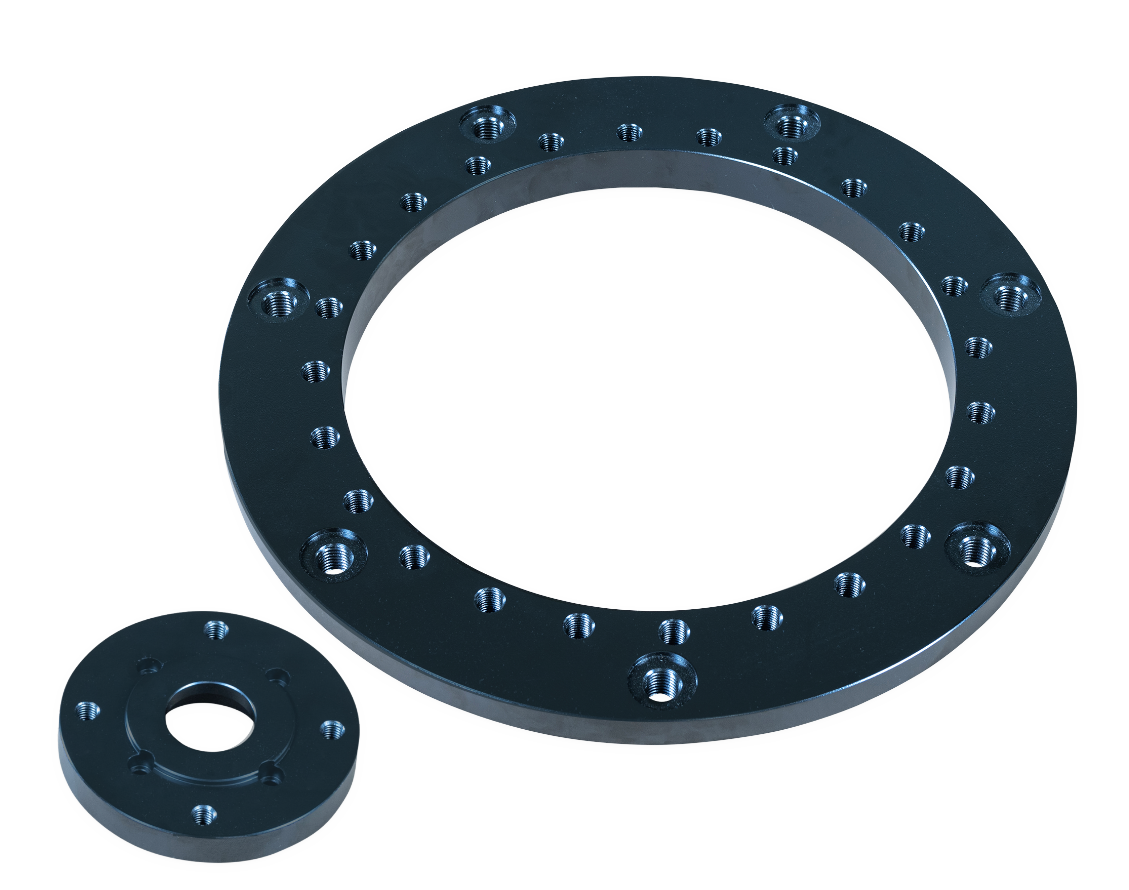

- Galvanising

- Balancing

- Hardening

- Nickel-plating

- Painting

- Powder coating

- Anodising

- Burnishing

- Sawing (up to 530 mm diameter)

Further processing

We offer you a wide range of options for further processing and finishing the parts we produce. Depending on the subsequent area of application, we can optimally protect the material from environmental influences by painting, powder coating, burnishing, nickel-plating, galvanising or anodising. Welding work, grooving (drawing and shaping), balancing and hardening are also part of our range of services. We can also carry out sawing work in-house up to a diameter of 530 mm.

Advantages

- Further processing of your parts

- Everything from a single source –

you receive your finished parts directly from us - Surface finishing as desired

Quality

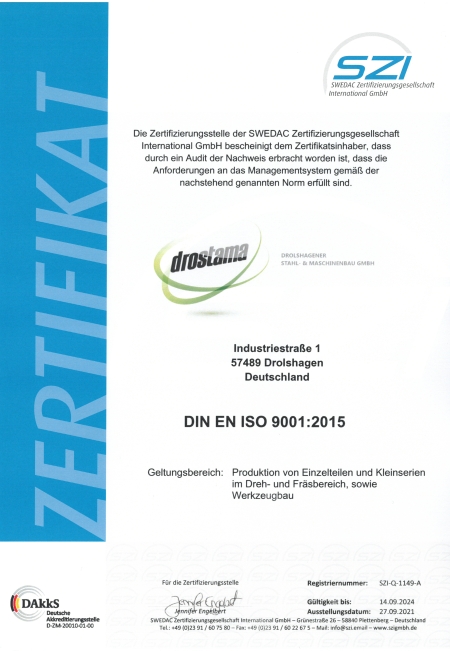

In order to do our best for you, we undergo a surveillance audit at regular intervals. Processes, requirements and guidelines in our company are reviewed as part of this. In this way, we guarantee you a consistent quality standard – even for parts with standardised material and processing specifications. Our in-house quality assurance ensures compliance with dimensional accuracy and material quality. Your orders can be individually marked with a marking device and also measured in 3D.

We are certified according to DIN ISO 9001:2015

In order to meet the diverse customer and production spectrum, we work together with renowned

German and international acceptance and classification societies.

This way we can demonstrably guarantee the quality of our products.

Quality assurance

Our in-house quality assurance ensures compliance with dimensional accuracy and material quality. Your orders are individually checked in our air-conditioned measuring room for compliance with the tolerances you require.